+86-139 6175 2624

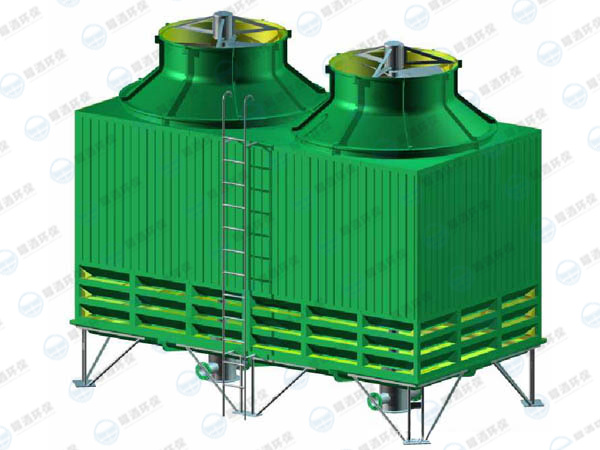

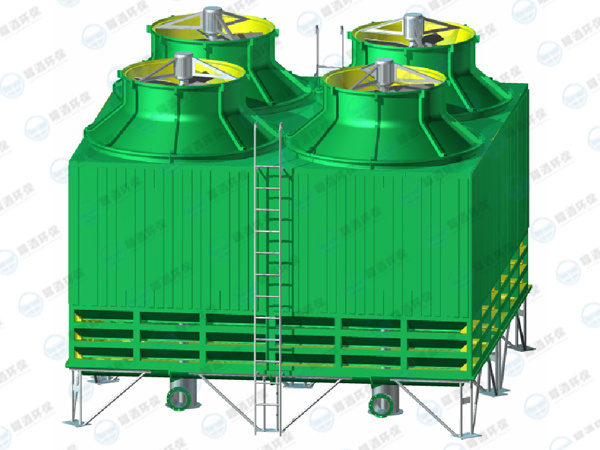

No filler spray cooling tower

Release date: 2017-10-24 14:29:46 Visits: 977

No power tower internal structure

Circular non-powered tower internal structure diagram

Advancing the atomizer

Operation diagram

1, WGFB unfilled spray cooling tower using high efficiency and low pressure centrifugal atomization device (nozzle pressure: 0.035MPa) as a cooling element to take [instead of the traditional packing tower packing and water distribution device, so that the entire tower almost become a empty tower, the structure of large simplify.

2, WGFB unfilled spray cooling tower After removing the filler and water distribution device, the atomizing device is installed above the air inlet. The water jet direction is the same with the cold air drawn by the axial fan, and the water rises and falls by two Process, cooling also co-current cooling and counter-current cooling of the two processes.

3, GFN unfilled spray cooling tower is sprayed into the mist through the atomization device, so that the air and water particles in uniform contact, and the packing tower is distributed through the water distribution cloth nozzle water to the film-like contact with the cold wind .

4, GFN tower due to the elimination of filler, the tower body load greatly reduced, do not need more support beams, civil structure simplification, saving civil investment.

Advantages of WGFB-unfilled spray tower:

1, resistance is small, cooling temperature difference, approximation is small:

As the WGFB tower cooling element (high efficiency low pressure centrifugal atomization device) to spray water into 0.5mm tiny droplets, the specific surface area is much larger than the specific surface area of the water is dispersed into a film-like filler, gas and water heat transfer surface area, and water Uniform, avoiding the dead zone caused by aging deformation and blockage of packing, and the ditch flow, leading to uneven temperature distribution in cooling point. The cooling effect is obviously lower than that of packed tower and the energy-saving effect is remarkable:

The working pressure of GFN low-pressure atomizer is only 0.035MPa, which is 0.17MPa lower than the working pressure of the autorotation atomizer of 0.2MPa, which greatly reduces the pump power. WGFB tower system resistance of about 1/2 of the packed tower, cooling water, the same fan, the matching motor power down to 60% of the packed tower, significant energy saving, combined with the elimination of cleaning and replacement of filler and nozzle cloth costs, operating costs Greatly reduced.

WGFB tower due to the elimination of packing, tower system resistance dropped to 1/2, under the same fan, the fan curve shows that the air volume increased to 1.2 times the original. Gas-water ratio has also increased to 1.2 times the original, so the cooling temperature difference than the tower 2 ℃.

3, WGFB spray fog particles uniform, non-clogging, no maintenance, stable and reliable operation:

WGFB tower overcame a series of phenomena that affect tower and process system equipment performance, such as packing tower packing aging, deformation and embrittlement, water blockage and flushing, filler blockage pipes, pumps and heat exchangers. Its life expectancy than the filler tower to extend more than three years.

Previous: Evaporative condenser and closed cooling tower

Next: Turbine cooling tower